Automation

“From users for users.”

Patrick Dietz, Director of Automation

Our software brings us closer to the hardware, and this is reflected in just how flexible and intuitive your operation becomes. Final programming is carried out in close cooperation with our customers. This ensures that they only get what they really need, and adaptations during the project and later expansions are no problem for us.

In addition to new plants, the advantages of our software are also evident during retrofitting of older systems. This also applies to systems that are not manufactured by us, as, for example, we can convert your system from Siemens S5 to S7.

We can create or provide interfaces to superordinate systems (PLS, ERP, MES or other control systems). We are more than happy to conform to any standard in partner systems in this respect.

Standard procedure here is the use of software products from Siemens (TIA Portal, WinCC Advanced, WinCC Professional).

Programming of machinery we manufacture involves assistance from the TIA Portal as a standard feature and the use of WinCC Advanced. It is optimally coordinated to system and customer requirements and is a state-of-the-art solution. The modules employed are open and non-proprietary. In addition, common programming standards (SCL, FUP) are adhered to, and this also allows the customer to realise subsequent software maintenance or expansions.

The machine is operated via a touchscreen display or central PC system. We take the wishes and requirements of the future plant operator into consideration during this. We are also more than happy to virtualise the existing infrastructure and visualisation systems in cooperation with the customer.

Following consultation with the customer, F-Secure control systems are employed here to ensure system security in complex systems such as our KEG plants. This enables us to achieve a high security standard, but also a reduced installation effort.

Our ALFlex Maschine stands out with the following features:

- Intuitive operation

- Flexible programming for innovative requirements

- Our programmers make all the difference:

Made by users for users! - Plant-optimised programming

- Rapid adaptation in the machine during active operation

- Open program code

We can provide the following on request:

- Virtualisation of PC hardware

- Integration of existing systems

- Flexible realisation of interfaces for process control, MES and ERP systems

Our processes stand out with the following features:

- Intuitive operation

- Flexible programming for innovative requirements

- Our programmers make all the difference:

Made by users for users! - Process-optimised programming

- Simple licensing and secure update capability

- Adaptations to the programming in the event of process changes can be made quickly during active operation.

- Open program code

We can provide the following on request:

- Virtualisation of PC hardware

- Simple distance and route control

- Flexible realisation of interfaces for MES and ERP systems

Our ALFlex Tools products are developed in our company. This means that we retain the knowledge. Requirements in individual applications are mainly derived from current projects or inquiries from our customers. Consequently, implementation always takes place in close cooperation with the users.

Our ALFlex Tools stands out with the following features:

- In-house development and knowledge

- Intuitive operation using Tooltips

- Web-based applications

- Clear navigation structure

- Database-oriented applications (MS-SQL-DB)

- Tools can be deployed independently

We can provide the following on request:

- Systems house solutions

- Integration in existing virtual systems

Values can be graphically depicted and evaluated from a table (e.g. database, csv) using ALFlex Trend. The desired values are recorded using OPC clients or corresponding PLC functions.

It is a standalone application which does not require any other products from the ALFlex family.

Our ALFlex Trend stands out with the following features:

- Web-based application

- Easily create and copy data fields

- Values are only saved in the event of hysteresis violation (saving memory)

- Freely parameterisable pens

- Intuitive operation using Tooltips

- Clear navigation structure

Sequence processes can be graphically depicted and evaluated using ALFlex Report. The desired values are recorded using OPC clients or corresponding PLC functions.

It is a standalone application which does not require any other products from the ALFlex family.

Our ALFlex Report stands out with the following features:

- Step logging and depiction of the program sequence

- Printing of report or saving as PDF

- Batch reference (predecessor/successor principle) can be established

- Events and interventions are recorded

- Adaptations to meet customer requirements are possible (quantity recording, etc.)

Database values can be loaded into a PLC through process control using ALFlex Rezept. Values can be reused for the required procedure here on the basis of a recipe. The desired values are transferred using OPC clients or appropriate PLC functions.

It is a standalone application which does not require any other products from the ALFlex family.

Our ALFlex Rezept stands out with the following features:

- Uncomplicated creation and copying of recipes

- Independent options for expansion and adaptation

- Intuitive operation using Tooltips

- Clear navigation structure

- Authorisation system

We can assign a unique ID to your container using ALFlex Gebinde and record this in a database together with the master data. This facilitates the realisation of a variety of tasks (maintenance assignments, storage location management, label printing, etc.) and it does not matter whether your containers are KEGs, wooden barrels, IBCs or other vessels.

The ID required for unique identification of the container can be a barcode, QR code or transponder. The knowledge required for reading (camera systems, antennae, etc.) also comes from our company. The desired data is recorded using OPC clients or appropriate PLC functions.

It is a standalone application which does not require any other products from the ALFlex family.

Our ALFlex Gebinde stands out with the following features:

- Unique ID and recording of master data

- Realisation of a variety of tasks (maintenance assignments, storage location management, specific container label, etc.)

- Application options ranging from wooden barrels to IBCs

- Adaptations to meet customer requirements are possible

Our ALFlex Trace application is used to document cleaning processes for containers of all types, regardless of whether documentation should be realised on the basis of technological values, images or user inquiries. ALFlex Trace records all values and stores these in a database together with a unique process number. The application can work with a barcode, QR code or RFID for container identification.

All data relating to documented cleaning processes can easily be subsequently retrieved using the application. Should the proper cleaning process be called into question as a result of poor product quality, ALFlex Trace can provide you with the answer.

It is a standalone application which does not require any other products from the ALFlex family.

The application contains two components:

- Windows tablet app for entering/recording data

- Web application for viewing documented cleaning processes

ALFlex Trace stands out with the following features:

- Simple user guidance

- User authentication based on a superordinate system is possible

- OPC UA interface for system control

- Printing of cleaning receipts

- Reporting of a cleaned container to a superordinate system is possible

- Convenient depiction of documented cleaning processes

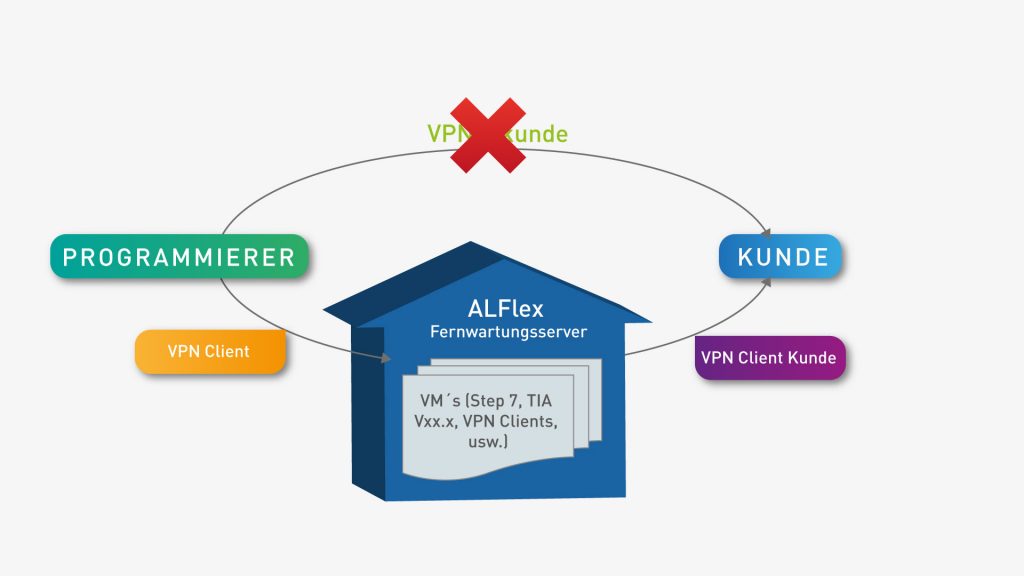

Naturally enough, we also provide an appropriate software service for all our ALFlex products. The integration of dial-up clients as well as in-house access solutions in our remote maintenance servers and connection to the computer centre allows us to assist our customers as quickly as possible in the event of a plant shutdown or other problems.

We also provide a variety of service packages. These can range from a regular inspection of the control system to securing relevant values in a database. We are also more than happy to create a tailored solution for your plant.

Our ALFlex Service stands out with the following features:

- The latest PLC program on the remote maintenance server

- Up-to-date dial-in client and access data

- High responsiveness

- Monthly report on current events and faults

- Data cleansing and archiving

- External PLC and database backups

- Predictable annual costs