KEG systems

“We perfect KEG.”

Peter Wiedemann, Director of Plant Construction

The introduction of the KEG system in 1964 revolutionised filling technology in breweries and for beverage manufacturers. ALBERT FREY AG focused from the outset on further development of this new technology, which is why we possess extensive knowledge and expertise today which we make use of when planning and designing your filling plant.

Our KEG solutions stand out with the following features:

- Finest cleaning and filling characteristics

- Maintenance-friendly components and a cost-effective service

- Automatic processing of all keg types

- Maximum reliability

- Hygienic design and high functionality

We can provide the following on request:

- Filling of disposable and special containers

- Fully automated dust cap removal

- Fully automated closure of large cans

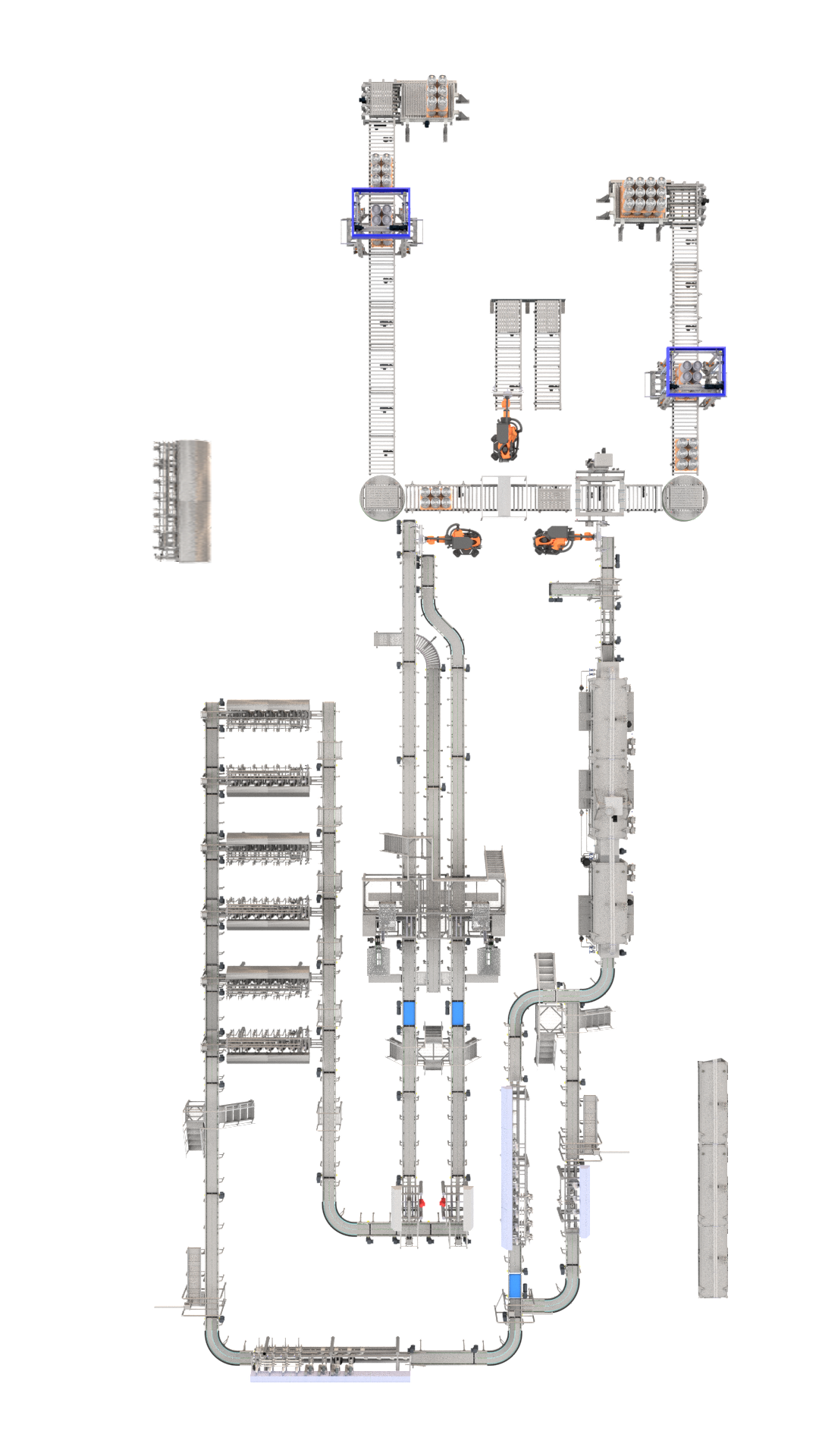

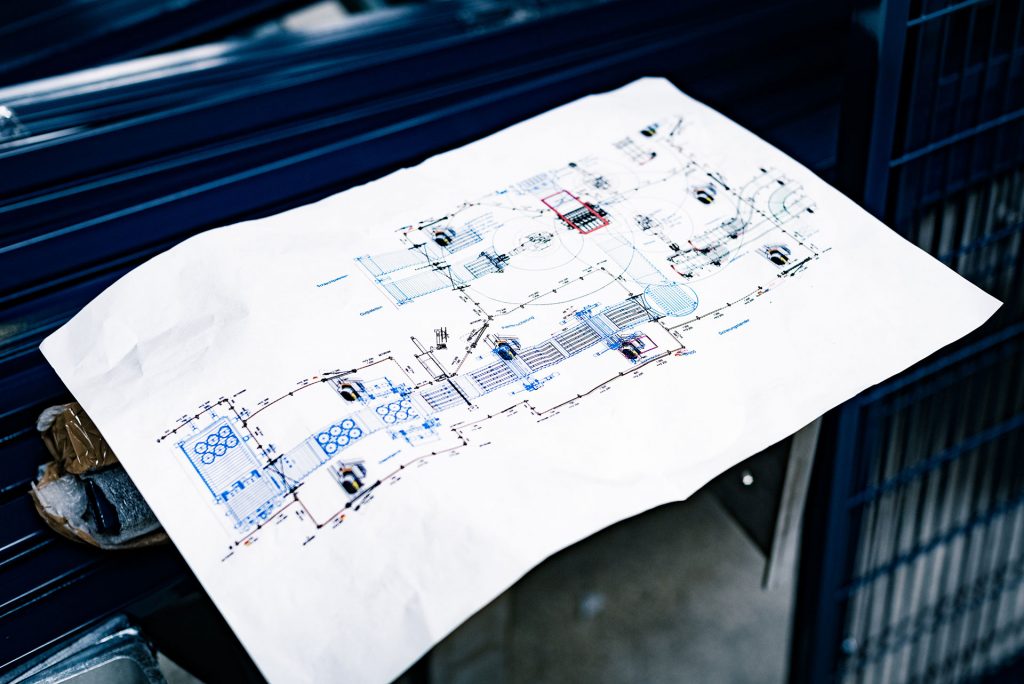

With you from the planning stage

- In 2D and 3D (AutoCAD; Inventor)

- Simulations using Process Simulate VC Lite

- Individual customer requests

- High degree of flexibility

- Optimum plant installation

- Direct contact

Simple operation

- High automation level

- Well-conceived operating and safety concept

- Central touch operating stations

- Visualisation of overall system and fault messages via large screens

- Optimum accessibility and cleanability of units

Automatic processing of all keg types

- Stainless steel keg 10 – 50l

- PLUS keg 10 – 50l

- ECO keg 5 – 50l

- Party keg 10 – 30l

- GSG keg 10 – 20l

- Finnkeg 15 – 30l

- Optikeg 10 – 20l

- Gokeg 10 – 20l

- Disposable keg